Barcode 1D | 2D

On this page you will find the characteristics of the barcode, what this term means, learn more about the types of barcodes, as well as something about their control, as well as its specific use in different areas.

Characteristics of a barcode

Barcodes fall into the field of "automatic identification", or in other words, into the field of "keyless data registration". Magnetic codes used, for example, on credit cards, or machine-readable OCR, RFID technology, also fall into this area. However, barcodes are the most widely used for various reasons.

How barcodes work

Each code consists of dark lines and light spaces that are read by sensors that emit mostly red light. This light is absorbed by the dark lines and reflected by the light spaces. The sensor detects differences in reflection and converts these into electrical signals corresponding to the width of the lines and gaps. These signals are converted into numbers or letters, which the corresponding bar code contains. This means that each digit or letter is recorded in the bar code using predefined line and space widths. The data contained in a barcode can include anything: a manufacturer's number, a product number, a storage location, a batch number, or even the name of a particular person who is, for example, allowed to enter an otherwise enclosed area, etc.

Benefits of using barcodes

Accuracy - using barcodes is one of the most accurate and fastest methods to record large amounts of data. When manually entering data, an error occurs on average every three hundredth entry, when using a barcode the number of errors is reduced to one millionth, and most errors can be eliminated if a check character is incorporated into the code to verify that all other characters are read correctly. This is why, for example, in many countries, transfusion stations have been equipped with barcodes so that different donors can be distinguished 100 % and so that different blood cannot subsequently be used for the patient.

Speed - if we compare the speed of barcode data entry with keyboard entry, we find that even the best typist is at least three times slower than any scanner.

Flexibility - barcode technology is multi-purpose, reliable and easy to use. Barcodes can be used in a variety of different and extreme environments and terrains. They can be printed on materials resistant to high temperatures or, conversely, extreme cold, on materials resistant to acids, organic solvents, abrasion, excessive moisture, etc. Their dimensions can even be adapted so that they can be used for miniature electronic components.

Productivity and efficiency

Foreign materials report that, for example, the use of barcodes in supermarkets increases the productivity of checkout staff by at least 30%. In addition, it is possible to know at any time, and in great detail, the stock status of individual goods in the warehouse. A study carried out for the US Department of Defense has shown that in some areas, the introduction of barcodes has increased efficiency by up to 400%.

Types of barcodes

There are several types of barcodes, each with its own characteristics. Some can only encode numbers, others can encode letters, and some can even encode special characters such as the dollar sign or the "" a ">" sign, etc. Each type of code has its own way of encoding individual characters into a system of lines and spaces. Since there are about 200 types of barcodes known in theory, it would be inefficient to describe them all, so we will only list the most commonly used ones.

EAN

This is the most well-known code for goods sold in the commercial network. This code can be used by any country participating in the international GS1 association (formerly IANA EAN - International Article Numbering Association EAN).

The EAN barcode can encode the digits 0 to 9, with each digit encoded by two lines and two spaces. It can contain either 8 digits (EAN-8) or 13 digits (EAN-13). The first two or three digits always identify the country of origin (e.g. Slovakia has the number 858), some other digits (usually 4 to 6) identify the manufacturer and the following digits, except the last one, identify the specific goods. The last digit is the control digit. It is the one that verifies the correctness of the decoding. Numbers are assigned to individual countries by the Brussels-based GS1 Association, and numbers are assigned to manufacturers by GS1 Slovakia in the Slovak Republic.

(Note: The graphical representations of the above codes and their data content are for illustrative purposes only.)

Code 128

This code also belongs to the EAN system. It allows you to encode a lot of useful information about a given product, such as delivery number, date of manufacture, date of packaging, minimum shelf life, weight, length, width, area, volume, to whom the goods are to be sent, etc. Each piece of information has its own numeric prefix (a defined combination of numbers) that uniquely identifies what type of information it is. Code 128 is capable of encoding a total of 102 characters. Each character is represented by three commas and three spaces.

ITF code

Because this code allows a high writing density (up to 8 characters per 1cm), it is very widely used in a wide variety of industries. It is also used in the marking of transport units. It can encode digits 0 to 9, with each digit encoded with either five lines or five spaces. Individual digits are encoded in pairs, i.e. the first digit of a given pair is encoded by the lines and the second by the spaces of those lines, so that an ITF code must always contain an even number of digits.

(Note: The graphical representations of the above codes and their data content are for illustrative purposes only.)

Code 39

A very common code used in a wide variety of applications, with the exception of retail sales. It is standard in the automotive, medical, defense, and many other industries and trades. It is capable of encoding the digits 0 to 9, the letters A to Z, and seven other special characters, each character represented by five lines and four spaces. It has been estimated that when using Code 39, decoding errors can occur after approximately 30 million characters have been read.

Codabar

This is one of the oldest codes. This code is used internationally to label blood banks in transfusion stations. It is capable of encoding the digits 0 to 9 and six special characters. Each character is represented by four lines and three spaces and offers a choice of four start and end characters that can be used to separate the data type.

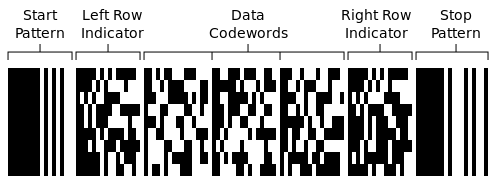

PDF 417

The next generation of bar code - a two-dimensional code with very high information capacity and error detection and correction capability (for code violations). PDF 417 is a patent of SYMBOL Technologies. The designation PDF 417 (Portable Data File) is based on the structure of the code. Each code word consists of 4 lines and 4 spaces with a width of at least one and at most six modules. However, the total number of modules in a word is always exactly 17.

(Note: The graphical representations of the above codes and their data content are for illustrative purposes only.)

Unlike traditional barcodes, which usually serve as a key to search for data in some external system's database, the PDF 417 carries all the data with it and thus becomes independent of the internal system. Not only ordinary text, but also graphics or special programming instructions can be encoded into the PDF 417. The size of the data file can be more than 1 kB. Examples of use include various identification cards, driver's licenses (in some US states). PDF 417 can also be used to encode patient diagnosis, etc.

Other types and groups of codes

The GS1 DataBar family of codes can be considered as a separate group . The DataBar barcode has been adopted as a standard by GS1 for its high flexibility and data capacity. It can encode considerably more information in approximately the same area as, for example, a conventional EAN-13 code. This makes it ideal for the labelling of small products, for example in the food and drug industry, in stationery shops and so on. The higher data capacity in a small footprint also enables the encoding of other important data for commercial operations, such as variable weight, shelf life, batch, serial number and many other parameters according to standardized application identifiers.

GS1 DataBar codes encode a unique identification number according to the global GTIN unique numbering system as standard (e.g. for small fruit or cosmetics), or an extended version with additional data (e.g. for meat products date of production, batch number for possible traceability of origin, etc.).

Full details on the standard and the use of these codes can be found at GS1 Slovakia.

The so-called 2D codes (two-dimensional) are also widely used, which significantly expand the data capacity of the standard linear 1D codes. In addition to the above-mentioned PDF 417 code, this group includes, among others, DataMatrix, Aztec, MaxiCode, Codablok and QR Code. Although these codes require a different scanning technique (so-called imagers or CCD cameras), due to their minimized space requirements and the possibility of encoding special characters, graphics, photos or fingerprints, they are used, for example, in the electronics industry, in healthcare, in the identification of persons and documents, in the use of direct marking technology (DPM), etc.

Examples of 2D codes are DataMatrix, Aztec, MaxiCode and Codablok.

Each of them contains the text KODYS SLOVAKIA8589000000651, but with different X and Y magnification factors.

QR Code has also become very popular. In addition to the advantage of high capacity, it is also readable by a normal mobile phone, even from a display or monitor, etc. This capability is already commonly used, for example, for quick mobile access to specific Internet pages, in marketing, advertising, etc.

The possibility of scanning the code also with a conventional camera on a mobile phone with a freely accessible application has opened the door for the "colour" dimension of barcodes. Colour 2D codes such as ColorCode, HCCB (High Capacity Colour Barcode) or Ultracode use the colour gamut to further increase data capacity and reduce the required area. As they are even beautiful and eye-catching, they are mainly used in imaginative marketing.

Barcode inspection

All barcodes must have a 'buffer zone' before the first and after the last line, in the colour of the spaces, the size of which is precisely defined. In addition, most types of codes have so-called marginal characters at the beginning and end. Meeting both of these requirements makes it easier for the scanner to read the codes and to distinguish the code from the other components of the package. So-called discontinuous codes, e.g. Code 39 and Codabar, must have spaces separating the characters. In order to be used to their full advantage, barcodes must be printed to the appropriate standards, because only high-quality printing guarantees a 100% reading success rate. When determining the quality of a barcode, the following are evaluated:

Minimum reflectivity - achieved from the darkest line. Important for clear recognition of lines and gaps in the code. If it is greater than half of the maximum reflectivity (the palest spot in the code), the code is unsatisfactory.

Code contrast - the vast majority of sensors sense under red light. In order for the sensor to safely distinguish between lines and gaps, the two elements must appear sufficiently contrasting i.e. the difference between the minimum and maximum reflectance must be as large as possible. The values of the minimum permissible contrast are predefined for each barcode type. If the actual contrast is lower than the minimum allowed contrast, problems could arise when reading the code.

Transition contrast - is the difference in reflectance of two adjacent elements (line and space pair). If the difference of either pair is less than 15 %, it is judged to be unsatisfactory.

Modulation - the ratio of the minimum reflectance to the total code contrast. Most often occurs in substrate transparency, when some parts of the code are less reflective than others.

Errors - the occurrence of ink dots in gaps or poorly printed lines. If the error is too large, it may be mistaken for a bar code element that either cannot be decoded or will be erroneously decoded.

Decodability of line and gap widths - the ideal dimensions of individual lines and gaps are precisely specified for each code. In order for the code to be reliably readable by any of the commonly used sensors, the width of the lines and spaces must not deviate from the required values by more than the tolerance allowed. The value of the tolerance depends on the type of code and its size (write density). The larger the code size (i.e. the smaller the write density), the larger the tolerance.

Computation - basic evaluation of the recognized lines to determine if the data is stored in them in accordance with the algorithm prescribed for the code type, including guard zones, check digits, and code structure (start/stop characters, etc.).

Protection zone - In order for the scanner to be able to safely distinguish the barcode from its surroundings, the size of the protection zone, which is precisely defined for each type of code, must be respected.

The quality assessment of the barcode is specified in the CEN (Comité Européen de Normalisation) and ANSI (American National Standards Institute) standards. These standards are valid in the countries of the European Union and the USA respectively.

We offer professional services to check your EAN/UPC barcodes with calibrated verifiers, or sell them if you need to regularly check the quality of your barcodes at the input or output.

Use of barcodes

A barcode has a wide variety of uses. Here we list just a few applications:

Barcode in the warehouse - All stored goods are marked with a barcode. If some supplies are not barcoded by the manufacturer, they can be operationally tagged when they arrive at the warehouse. Marking is done by means of labels printed by a barcode printer. The most economical and fastest option is to label the shelves with the type of goods. The codes are scanned both when the goods are received in the warehouse and when they are dispatched. This allows not only to have a perfect overview of the current state of stock in the warehouse, but also to carry out a very fast and accurate inventory, to automatically track the minimum quantities of a given type of goods in the warehouse, to fill in delivery notes and invoices, and thus to speed up the whole process of dispatch, etc.

Barcode in production - In belt production, a barcode is fixed or printed on the product, which is usually remotely scanned by a laser scanner. With the help of a filing system, the data can be used to control the flow of products, the number of products produced, record the person who carried out the production operation, automatic delivery of materials, etc. The information obtained can of course be used for many other applications.

Barcodes for guarding objects - A guard making a round of a guarded object is equipped with a portable memory terminal with an integrated barcode scanner. Barcode labels are placed at several points along the guard's route (the code is not readable by eye - the content of the code is not written out). If a guard passes by the area marked with a label, he or she will scan the code into the terminal's memory. In addition to the checkpoint number, the time and date of the scan is automatically stored in the scanner's memory. When the patrol is completed, the authorised officer shall transfer the data from the terminal to the computer and carry out a check of the guard's activity.

Barcodes in courier services - The consignment is marked on receipt by the courier with a label printed on a portable printer, which is attached to the hand-held terminal and at the same time entered in the records of consignments received. When the courier arrives at the distribution centre, the data from the terminal is transferred to the central information system. The barcodes are further used for dispatch from the distribution centre for sorting by location of the consignee. The courier who delivers the consignment to the consignee scans the barcode with a portable terminal and enters the relevant data from the terminal keypad. If the terminal is equipped for this purpose, the recipient can sign directly on the terminal display. This eliminates complicated paper handling

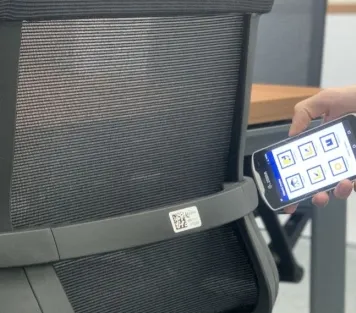

Barcodes in the company's asset register - Each item of tangible fixed assets or small tangible assets is marked with a label with a barcode that carries information about the inventory number of the asset. In case of damage to the bar code, the inventory number is also indicated on the label in conventional form. In addition, each asset object is characterised by its location, e.g. the number of the room where it is located. During asset registration (i.e. when taking an inventory of assets or moving assets), asset barcodes are scanned by a portable terminal with a built-in scanner. They are then transferred in bulk to a computer, where they are processed by a suitable asset registration programme. The program evaluates the retrieved data, i.e. notifies the operator of any detected discrepancies in the location of the assets and modifies the recorded location of the assets accordingly. In this way, a quick and easy update of the asset location database according to the current status is ensured.

Barcodes for access control - Each person authorised to enter a particular building has a badge (e.g. a plastic card) on which a barcode is printed. Upon entry, the code is scanned to prevent unauthorized persons from entering. At the same time, it is possible to know at any time which person is present in a given building. Similar badges can be issued to visitors. This system can be used in large companies, computer centers, sports complexes, medical institutions, etc.

Barcodes in Healthcare - There are three main areas of application in the healthcare industry for the benefits of accurate and unmistakable identification through barcodes. Special wristbands with a unique barcode can be used to identify patients and meet all hygiene and anti-allergy requirements. Special printers are used for the operational printing of these wristbands (wrisbands). Barcode medical equipment registration systems with appropriate software contribute to compliance with strict hygiene and safety regulations, cost savings, order maintenance and accurate record-keeping of prescribed maintenance or calibration of medical equipment and instruments. Without accurate, unmistakable and immediate identification of laboratory samples, transfusion preparations or blood derivatives using barcodes, these procedures are now unthinkable.

Barcodes in libraries (video lending libraries, cd-lending libraries, etc.) - All books and reading cards are barcoded. By scanning the codes on the books and at the same time the code on the library card of the reader who borrows the books, it is then possible to find out quickly and at any time which books have been borrowed by whom, or which books are in the library.