Marking storage positions in the C&A distribution centre as a basis for efficient use of the WMS

C&A, a fashion brand with a global presence, has built a distribution centre in CTPark near the village of Zavar, which will become the company's flagship store. It plans to supply branches in nine countries in the Central and Eastern European business region (Austria, Croatia, Romania, Slovenia, Serbia, the Czech Republic, Hungary, Poland and Slovakia).

The planning and structure of warehouse space in the distribution centres are very important in the introduction of modern technology. Of course, professional warehouse signage is also a prerequisite for the effective use of the WMS system.

C&A's distribution centre covers an area of 30 thousandm2 and consists of several warehouse zones. For each of them, it was necessary to design a special type of signage that facilitates work and orientation in the warehouse.

Signage:

- positions for clothing storage

- pallet positions located in the open area

- pallet positions located in racks

- shelf racks

- conveyor system positions

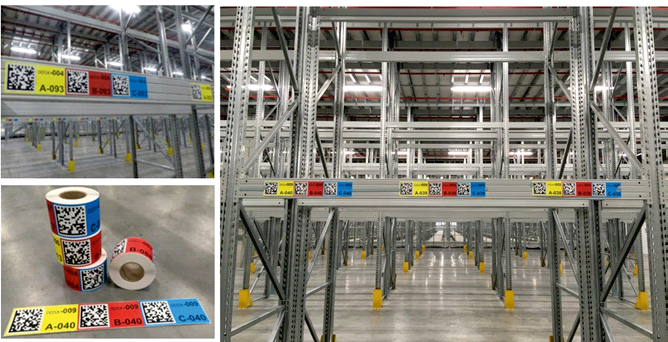

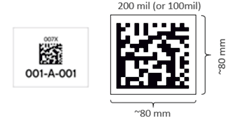

More than 49 thousand storage positions were labelled with labels made of highly durable materials based on a unique datamatrix code.

"Our distribution centre in Zavar is the company's flagship facility and we have worked with experts to build it. For the position labelling design and installation part, we approached KODYS SLOVAKIA as one of the companies, who have many years of experience in warehouse labelling. They understood our requirements right from the start and accordingly designed a suitable warehouse labelling system, which they applied very quickly and professionally."

Peter KIS

Warehouse Operations Manager

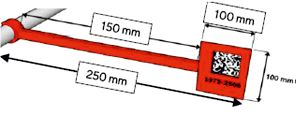

Position marking for garment warehousing

Requirement:

- Garments hung and stored on hangers

- marking of positions using plastic holders

- Quantity: 34 160 positions

Solution:

- manufacture of plastic holders according to the specified criteria from PPH Scolefin 52 G 13-0 material made up of 20% glass fibre to ensure no twisting

- installation of positions: 5 days

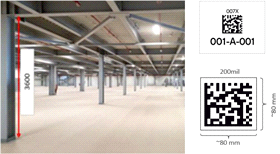

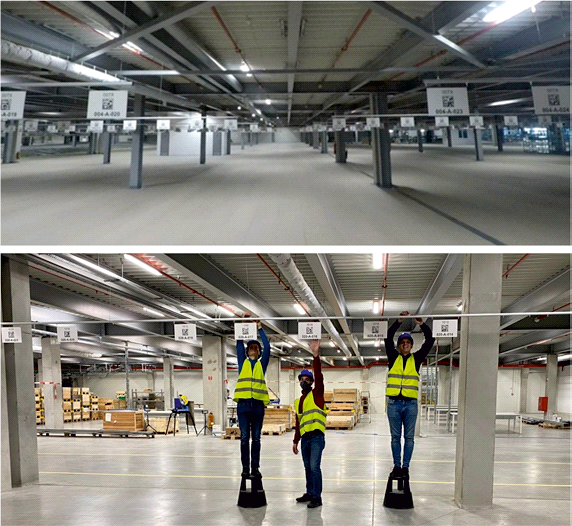

Marking of pallet positions placed on the open area

Requirement:

- Freestanding pallet positions

- ceiling height max. 4m, one sector approx. 12m

- Quantity: 3 559 positions

Solution:

- Use a special hanging rail system for easy hanging without interference in the ceiling

- possibility of moving individual positions if necessary

- 900 pcs of 2m suspended rails (1.8km of rails)

- installation time: 8 working days

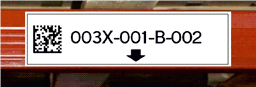

Marking of pallet positions in the racks

Requirement:

- Three-level pallet racking (3 pallets on top of each other)

- Quantity: 4 240 positions

Solution:

- Use of coloured "Multilevel" labels

- the warehouseman reads the positions from one central label located on the first beam

- installation time: 1 day

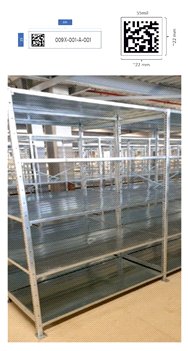

Shelf labelling

Requirement:

- Positions must be variable for repositionability

- quantity: 7 015 positions

Solution:

- Use magnetic labels for quick and easy handling

- installation time: 1 day

Labelling of conveyor system positions

Requirement:

- Tray marking

- Quantity: 559 positions

Our solution:

- 5mm comatex signs applied to existing structures in the warehouse

- installation duration: 1 day